Precision CNC Machining for the Medical Industry

Precision components for the medical industry, accuracy is of the utmost importance. This statement applies to manufactured parts throughout the industry. Whether it is medical equipment, biomedical implants, catheters and other medical equipment, ultrasound equipment, MRI scanners or diagnostic equipment, high-precision CNC machining will play a role.

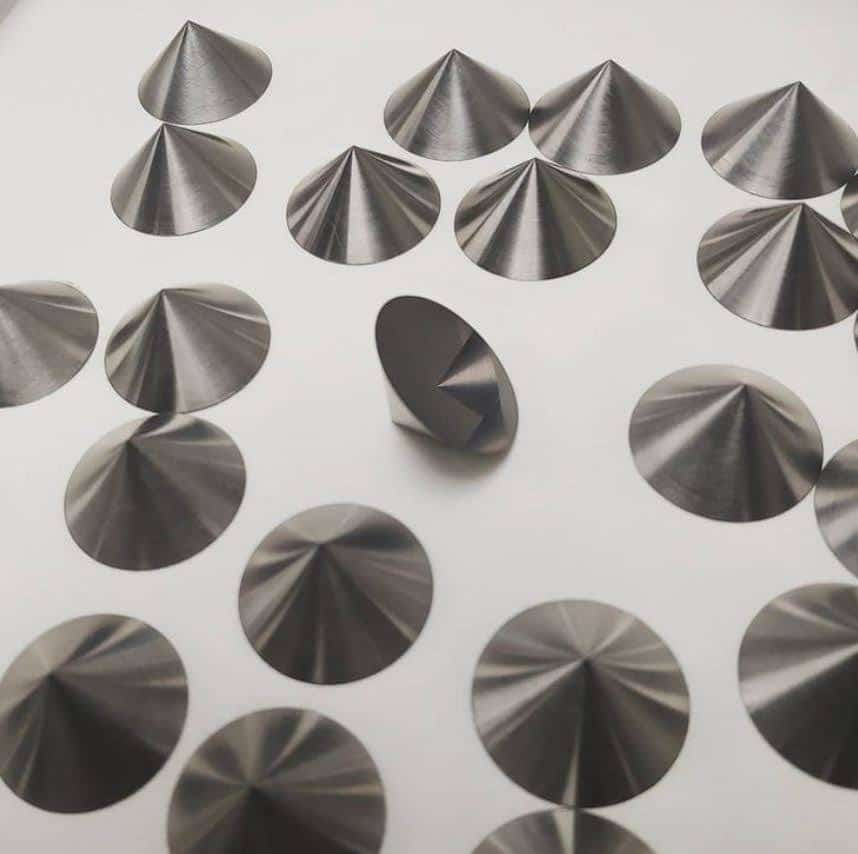

CNC machining is used in the medical field because it meets strict requirements for quality and consistency. Complicated surfaces and geometric shapes are not a problem, and the final product strictly complies with the safety and precision requirements of the medical industry. Medical equipment is complex, and there is no room for fault tolerance.

Metals like tantalum (Ta) and tungsten (W), as well as tungsten heavy alloy (WHA) and molybdenum are used in the radiation therapy market. Tungsten is used in anti-scatter grids, bearing parts, and collimators. High density tungsten is suitable for use in medical settings, research environments and for imaging equipment – anywhere where containing radiation is a key part of safety measures. Tantalum is used for field flatteners in medical linac machines.

Hospitals and medical settings make extensive use of ionizing radiation for medical imaging equipment as well as using nuclear medicine for both imaging and treatment. Nuclear medicine is heavily reliant on the use of radioactive isotopes, so hospitals need to have suitable isotope containers to store and transport radioactive materials.

Since 1984

We are proud to support our local communities with jobs that offer good working environment, excellent pay and benefits, growth opportunities and stability. Proud to be an American Manufacturer and a Woman Owned Business.

Contact Us Today