Custom Manufacturing Solutions

Particularly in the semiconductor industry, when you are using older equipment to do modern things, the way something was originally built doesn’t quite work for the way you want to use the equipment now. Pieces of your equipment wear out that are expensive to replace or perhaps not readily available new. Or, you realized through use that some small design changes could make things more reliable.

Inefficiencies become built into a manufacturing line when something does not perform as required for the task at hand. Designing for manufacturability is very important for keeping costs down, but so is designing for form, fit and function. Combining these two things can produce products that are truly inspired. We consider all aspects of the product when we are helping a customer with a custom solution.

When we start working with a customer on a custom solution to a problem, we focus first on understanding what the customer needs to have and then we work backwards from there to create a product that answers those needs. Functional design is, creating products that work well and produce a positive outcome.

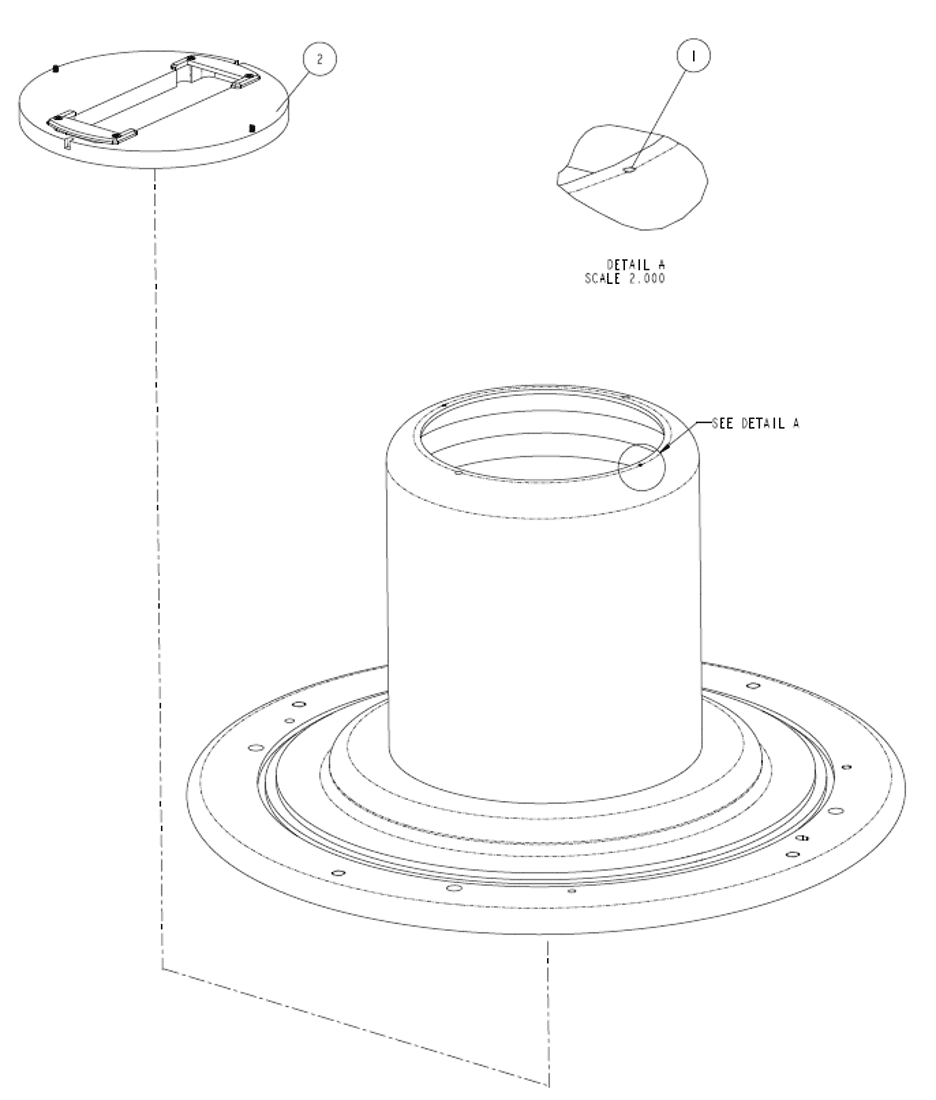

Problem

Stripped threads (1) prevent heat shield (2) from being mounted. Material is too thin to repair thread using helical insert.

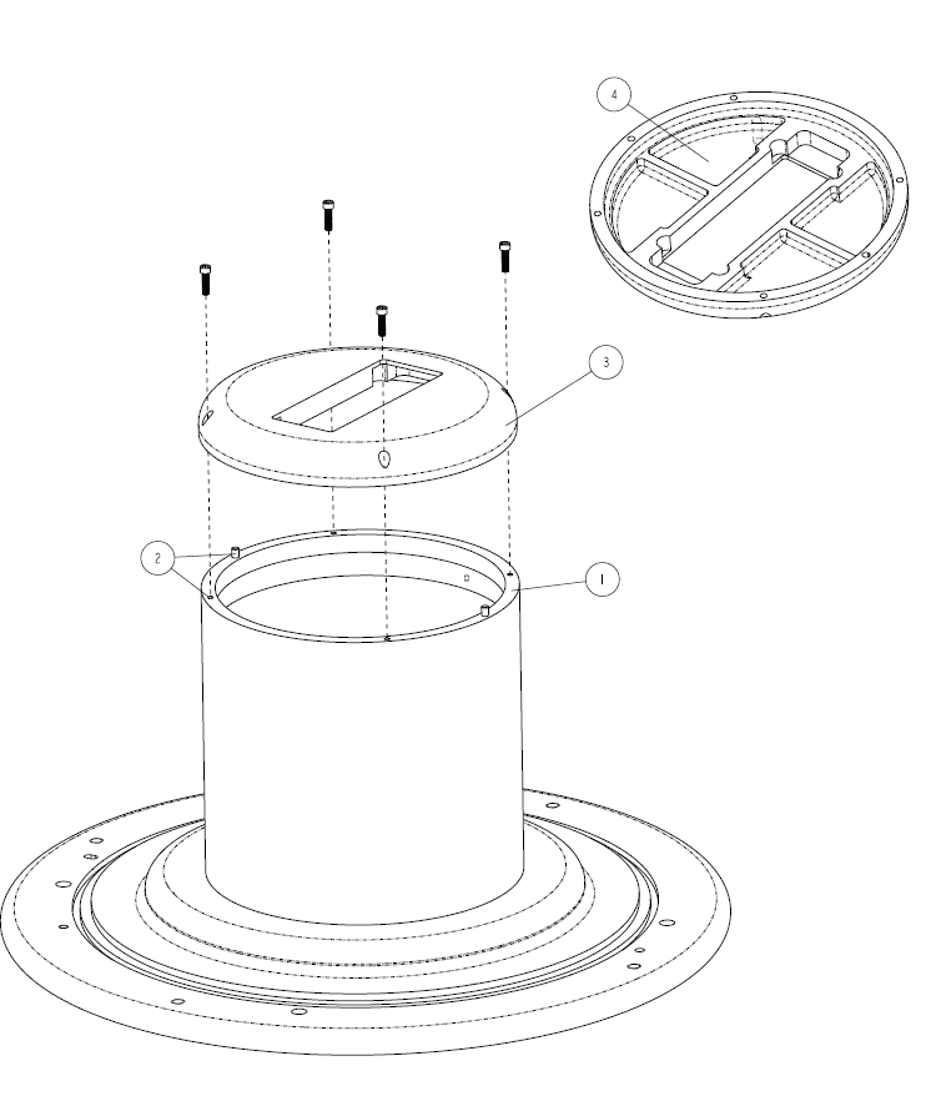

Solution

Damaged portion of shield is removed (1). Locating pins and threaded mounting holes (2) are added. Custom stainless steel cap (3) with heat shield features incorporated into its design replaces damaged portion of shield. Cap is strategically pocketed (4) to provide low net increase in weight.

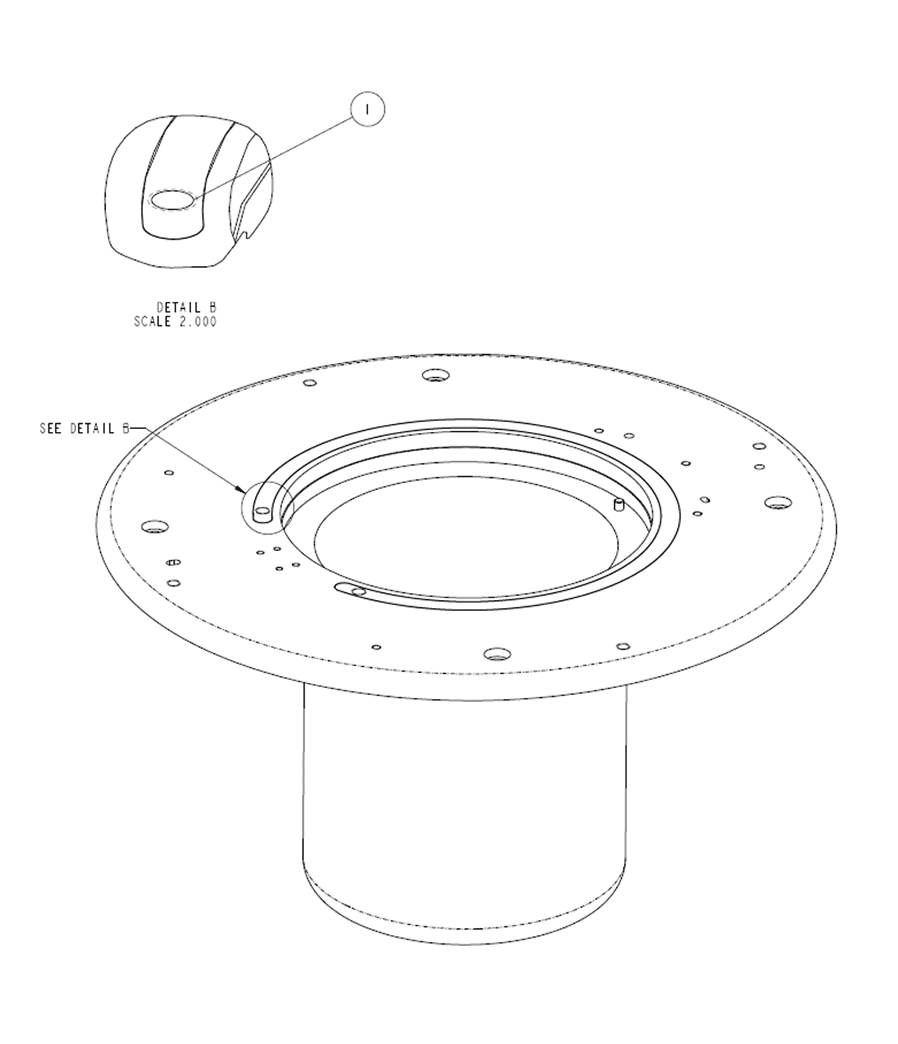

Problem

Water channel NPT threads (1) over time become stripped or too deformed to seal properly.

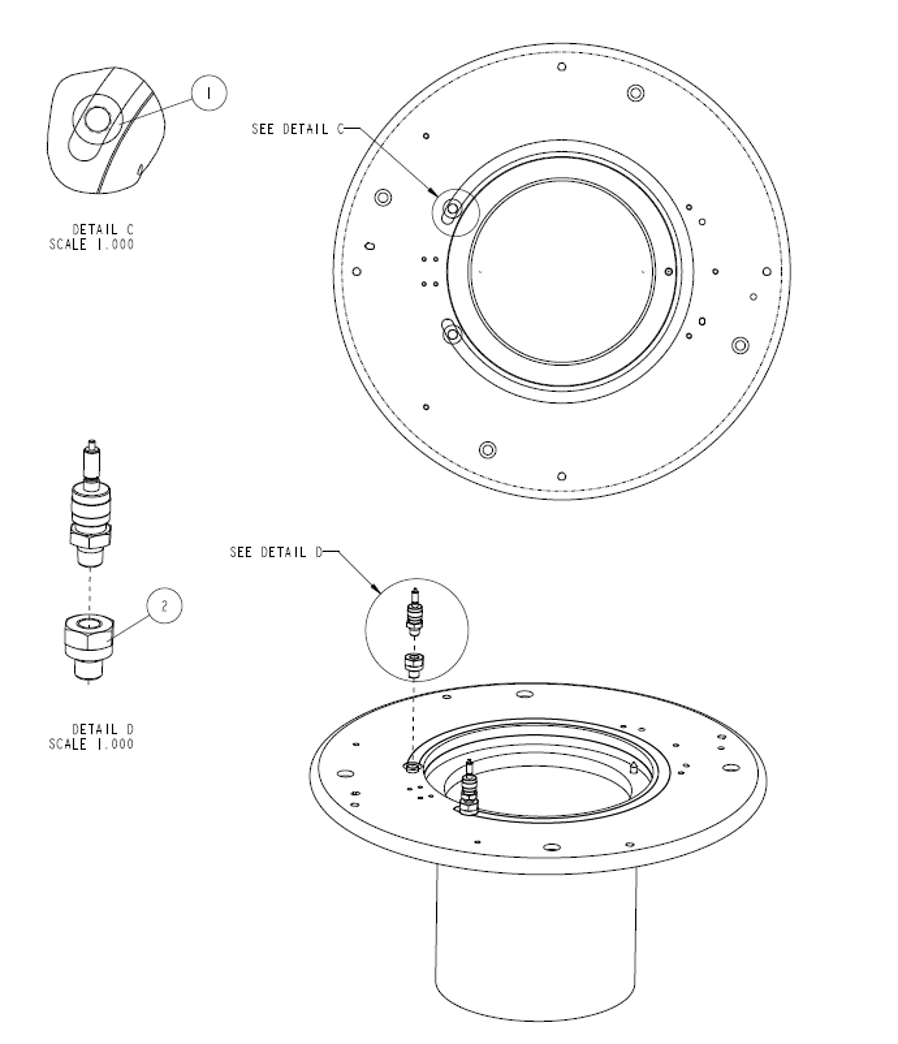

Solution

NPT holes are reworked to accept O-Seal fitting (1). Custom NPT to O-Seal adaptor (2) allows Quick Disconnect fittings to be connected to water channel. Fittings can be easily removed and reinstalled without degradation of thread.